Clean rooms at the CNRS – combining cutting-edge research with a reduced carbon impact

The lengthy seven-year renovation of the LAAS-CNRS laboratory's clean room finally came to an end. This project illustrates the way two CNRS laboratories have worked to reduce the energy consumption of their clean rooms for several years without affecting the quality of their research.

Clean rooms are bright and luminous but remain in the 'shadow' of the products they are used to manufacture. They are used to produce useful cutting-edge systems and products for both science and industry including semiconductors, medication and automotive/aeronautical components. For all these technologies, high levels of cleanliness in the air supplied combined with stable temperature and humidity levels are required. These are achieved by filtering and air-conditioning the air and maintaining room pressure at a stable and precise level. Energy-intensive equipment is required to maintain constant parameters including air humidifiers and dryers, extractors, absolute filters, and so forth. This means clean rooms are the main source of energy consumption for laboratories that possess them, with the corresponding negative 'knock-on' effect on the labs' greenhouse gas balance. The CNRS's environmental transition plan sets out the objective of continuing cutting-edge research while reducing the energy consumption of clean rooms. But how is this possible? This is the challenge taken up by two laboratories hosted by the CNRS, each in their own way.

The LAAS-CNRS - renovating infrastructure

Between 2018 and 2023, support from the CNRS and government funding enabled the Laboratory for Analysis and Architecture of Systems (LAAS-CNRS)1 to carry out a major energy renovation programme for its clean room. The room is around twenty years old and accounts for 80% of the laboratory's electricity consumption though only taking up barely 7% of its surface area. This Toulouse laboratory has over 700 staff members and specialises in the study of complex systems like robotics, transport and communication networks. Hugues Granier is in charge of the lab's micro and nanotechnology platform and explains the origins of this project: "When our clean room was built between 2005 and 2007, it didn't benefit from the same energy considerations as now and our laboratory chose particularly energy-intensive technical solutions. So, our goal was to bring a room designed twenty years ago up to modern-day standards which has resulted in some really impressive savings". The installation of photovoltaic panels and modulating dampers on the ventilation systems and a heat recovery system allied with enhanced energy expenditure monitoring have enabled the LAAS-CNRS to reduce its gas consumption by 76% and its electricity consumption by 37% (2023 figures compared with those from 2017). These measures alone have led to the LAAS-CNRS achieving the first objective of the tertiary sector decree around fifteen years ahead of schedule. This is a regulatory obligation introduced by the government in 2023 which stipulates that the entire tertiary sector must achieve a gradual reduction in its overall energy consumption of at least 50% by 2040.

This reduction is particularly welcome given the spectacular inflation in the price of electricity nowadays. The return on investment from this €2 million project only took two years instead of the initially planned five years. This remarkable energy saving has been accompanied by a similar reduction in the LAAS-CNRS's carbon impact given that gas emits three times more greenhouse gases than electricity in France.

Now, the LAAS-CNRS has moved on to dealing with uses of the clean room itself. As Hugues Granier explains, "you can always improve infrastructures but these days it's the process that consumes the most energy". Since September 2024, the clean room's tolerance threshold has been gradually raised for its temperature and humidity parameters outside operating hours. These are restored when operations resume and the impact of these changes on the quality of scientific experiments are assessed. Every degree of temperature counts, with the French Agency for Ecological Transition estimating that one degree higher or lower corresponds to a 7% increase or reduction in energy consumption.

The C2N: just consuming what's needed

The Centre for Nanoscience and Nanotechnology (C2N)2 on the Saclay plateau with its 400 staff members or so has set itself the objective of rethinking how its clean rooms are used. Sophie Bouchoule is a CNRS research professor at the laboratory who was recently appointed as its sustainable development coordinator which led to her finding herself in charge of the energy renovation of her cleanroom. The laboratory's general secretary Cynthia Vallerand explains to us how, "as the technology centre's scientific coordinator and as a user, Sophie Bouchoule was pretty much in the front line as regards the building's unsolved malfunctions and their impact on research. This and her professionalism led the Unit Director, Giancarlo Faini, and myself to ask Sophie Bouchoule to help us with making the building fully operational, which was completed at the end of 2022. After the success of this mission, the management naturally asked her to become our sustainable development coordinator to analyse energy losses and implement the right solutions to optimise energy consumption".

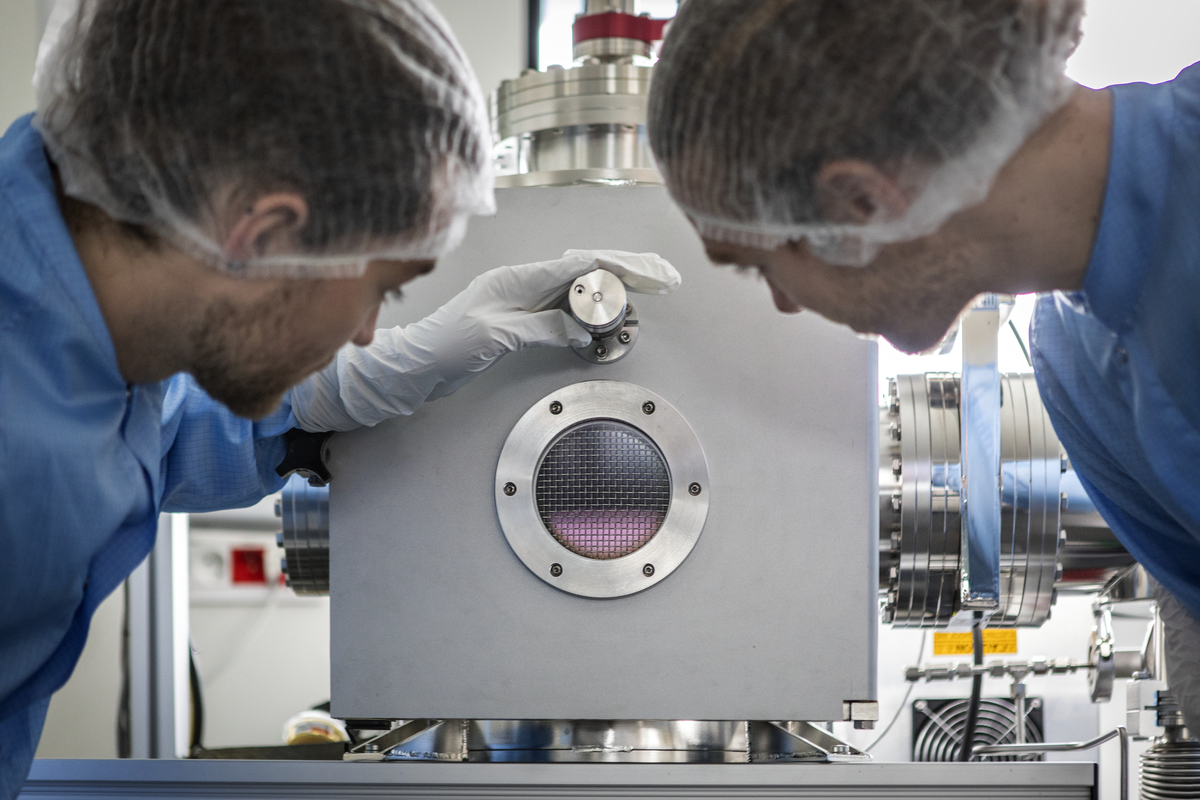

Sophie Bouchoule explains her analysis when the building was handed over: "In 2018, the building had just been delivered and had a number of defects so we decided to find out what was causing the issues. In this context, as end users we became aware of the colossal amount of energy needed to operate the cleanroom. The design of our building was just over ten years old but in 2021 its energy consumption just seemed very high! Once we'd realised that, we couldn't leave things as they were". A working group was set up, led by Sophie Bouchoule, a specialist in semiconductor optical transmitters, and Aristide Lemaître, who was awarded the 2024 CNRS Silver Medal for his work on semiconductors. They began analysing and questioning clean room practices with one credo underpinning their work – "just consume what you need" – and the group works with a range of connected sensors to achieve this. Aristide Lemaître, a CNRS research professor and the C2N's other sustainable development officer, explains that "measurement is key" in this area.

The group uses precise measurement data to identify the most energy-intensive items and practices in detail. In this way, the optimisation of the operating parameters of a heat exchanger installed between the cooling and heating networks to recover waste heat has enabled a 75% reduction in the unit's gas consumption by since 2022, in turn significantly lowering the building's carbon footprint. Sophie Bouchoule draws the clear and yet obvious conclusion that "installing an exchanger is very cost-effective for sites producing both hot and cold water".

Alongside this initiative, part of the clean room, where air processing accounts for 42% of the lab's total annual electricity consumption of 12 GWh, has been switched to reduced mode. This means the flow of fresh or recycled air is reduced while extending the tolerance around the temperature and relative humidity set points in the rooms when the clean room is unoccupied (from 8 pm to 6 am on weekdays and every weekend). When this reduced mode was implemented, the total electrical power the building consumed was reduced straight away by just over 20%, which represents annual savings of almost 1.4 GWh. All of this was achieved with no negative effect on the quality of research in the clean room. Sophie Bouchoule thinks this is because "the air mixing rates that set the theoretical cleanliness classes3 are sometimes out of proportion to usage, especially when the buildings unoccupied, so really the standards needed to be rethought". The C2N received support from the 2023 CNRS Low Carbon Call for Initiatives which has enabled it to extend this reduced mode to some of the lab's air conditioning and this operation paid for itself in under a year. At the start of 2025, C2N will begin more extensive work to improve the buildings energy performance, including further extensions of this reduced mode. This work is supported by the Île-de-France South regional offices technical and logistics department, the CNRS and the French government,

- 1A CNRS intramural research unit (UPR) associated with Insa Toulouse / Toulouse INP / Université Toulouse-III Paul-Sabatier.

- 2CNRS / Université Paris-Saclay.

- 3The classification of a clean room depends on the cleanliness of the air inside the room. The lower the concentration of particles, the higher the classification of the clean room.

Towards fair use of resources at C2N

The C2N is also analysing the consumption of its clean rooms other resources while reducing its consumption of gas and electricity. For example, the labs consumption of mains water has been reduced by 75% in just a year by commissioning a closed cooling water circuit – essential for the equipment – as has its consumption of helium.

This cryogenic liquid is used to run experiments at 4.2K (-269°C) which are essential for research in the fields of quantum physics, molecular chemistry and medicine. However, helium is extracted from the subsoil by exploiting natural gas and has been the subject of colossal inflation for several years. The price of a litre of liquid helium has gone up from a few euros in the mid-2000s to nearly thirty euros today. Helium is a rare gas that is unrecoverable once in the atmosphere, thus making it a "strategic resource to be preserved", as Nicolas Zerounian, senior lecturer at Paris-Saclay University and a member of the C2N working group on this subject explains. The laboratory has set up a closed helium circuit (as is the case for water) and recovers, compresses and liquefies up to 90% of its consumption (700 l/month) on site. Nonetheless, this virtuous circle has a cost – 22 kW on average for the compressors, the purifier and the liquefier. C2N now plans to recover the waste heat generated by the new equipment as it has already done for the clean room's air conditioning.

Two years of experiments later the C2N reports no change at all in the quality of the research carried out in its clean room which made it a lot easier for the laboratory's members to get on board with the changes. The same is true at the LAAS-CNRS where Hugues Granier notes there is a "consensus among users who are well aware of the environmental and safety issues at stake".

To go further with this initiative, the C2N and the LAAS-CNRS intend to share their respective experiences nationally, firstly within the French nanofabrication network 'Renatech' led by the CNRS which the two laboratories belong to. Secondly the initiatives developments have been documented in technical articles or shared in the framework of the Labos1point5 research network which aims to enhance understanding of the carbon footprint of research so it can be reduced. Emmanuel Vialan is the head of the real estate and logistics department at the CNRS West Occitania regional office and also heating, ventilation and air conditioning energy performance renovation officer at the CNRS's Financial Strategy, Real Estate and Modernisation Department (DSFIM). He supported the LAAS-CNRS's renovation and confesses that although "there is currently no national-level policy on clean rooms, discussions are underway to optimise energy consumption in two of Renatechs other clean rooms – the Institute of Electronics, Microelectronics and Nanotechnology in Lille and the FEMTO-ST Institute 'Franche-Comté Electronics Mechanics Thermal Science and Optics – Sciences and Technologies' in Besançon, neither of which are CNRS buildings". This coordinated approach chimes with Sophie Bouchoule's observation that "if we all work together, we can solve these problems".

Experiments in this area remain rare but testify to the CNRS's pioneering nature, as Fabrice Cocheteux, head of the DSFIM's buildings policy department told us. "These achievements are a great source of satisfaction for the CNRS. They testify to our organisations strong commitment to keeping control of energy and environmental costs so we can enhance the quality of life and research in our laboratories. Of course, the CNRS is implementing its energy renovation strategy in all of the 530 or so buildings we operate over around a hundred sites but the very specific installations associated with experimental research are particularly important. These are highly demanding in terms of air conditioning, filtration, extraction and compensation which of course represents very significant energy consumption. This is the case of clean rooms like at the LAAS-CNRS and the C2N. These are two major technology platforms that have benefited from significant energy performance improvements thanks to the commitment and expertise of teams from our units and regional offices".